shoemaking

pattern making, materials, Cutting, lasting, stitching, design & making

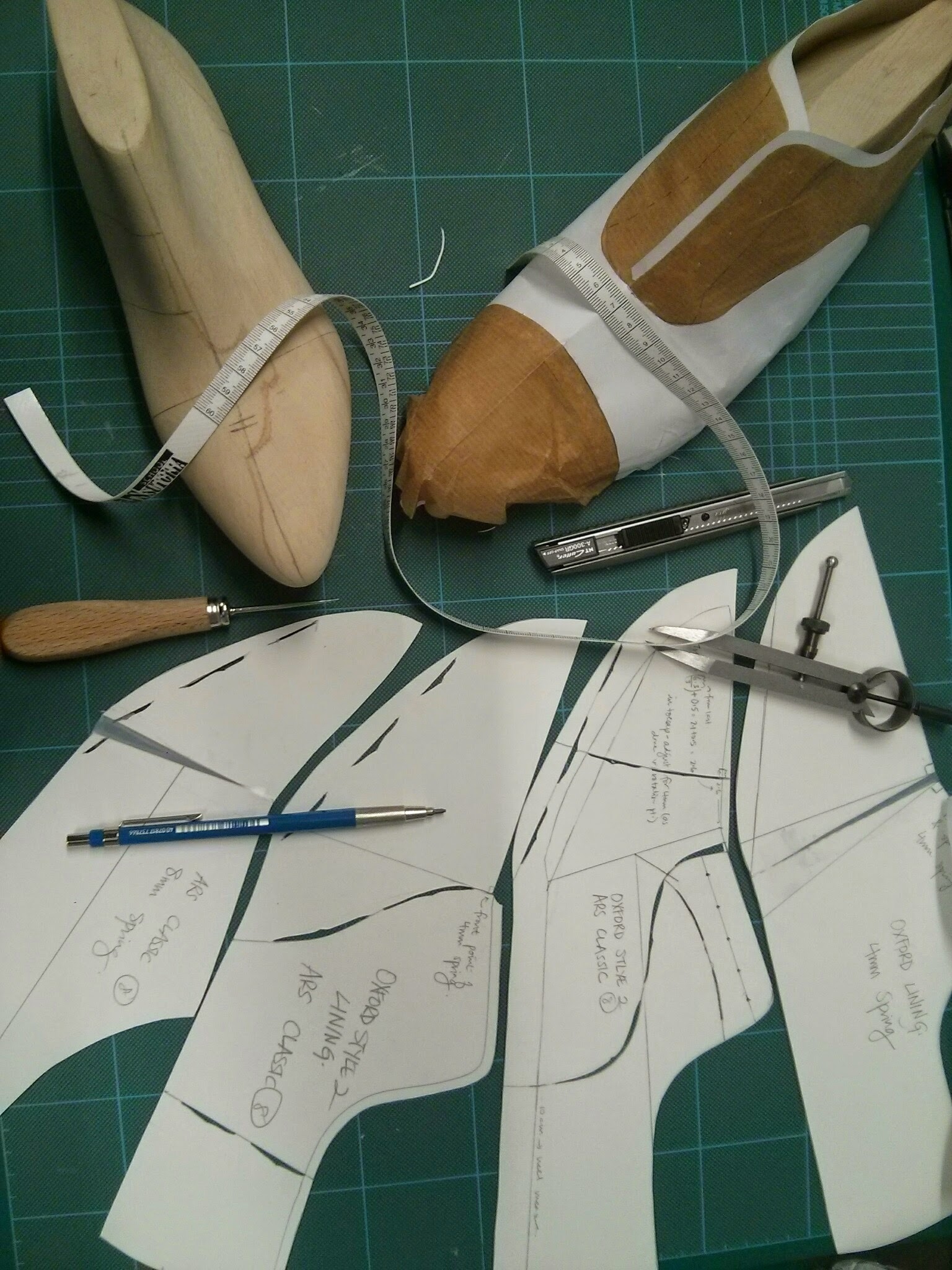

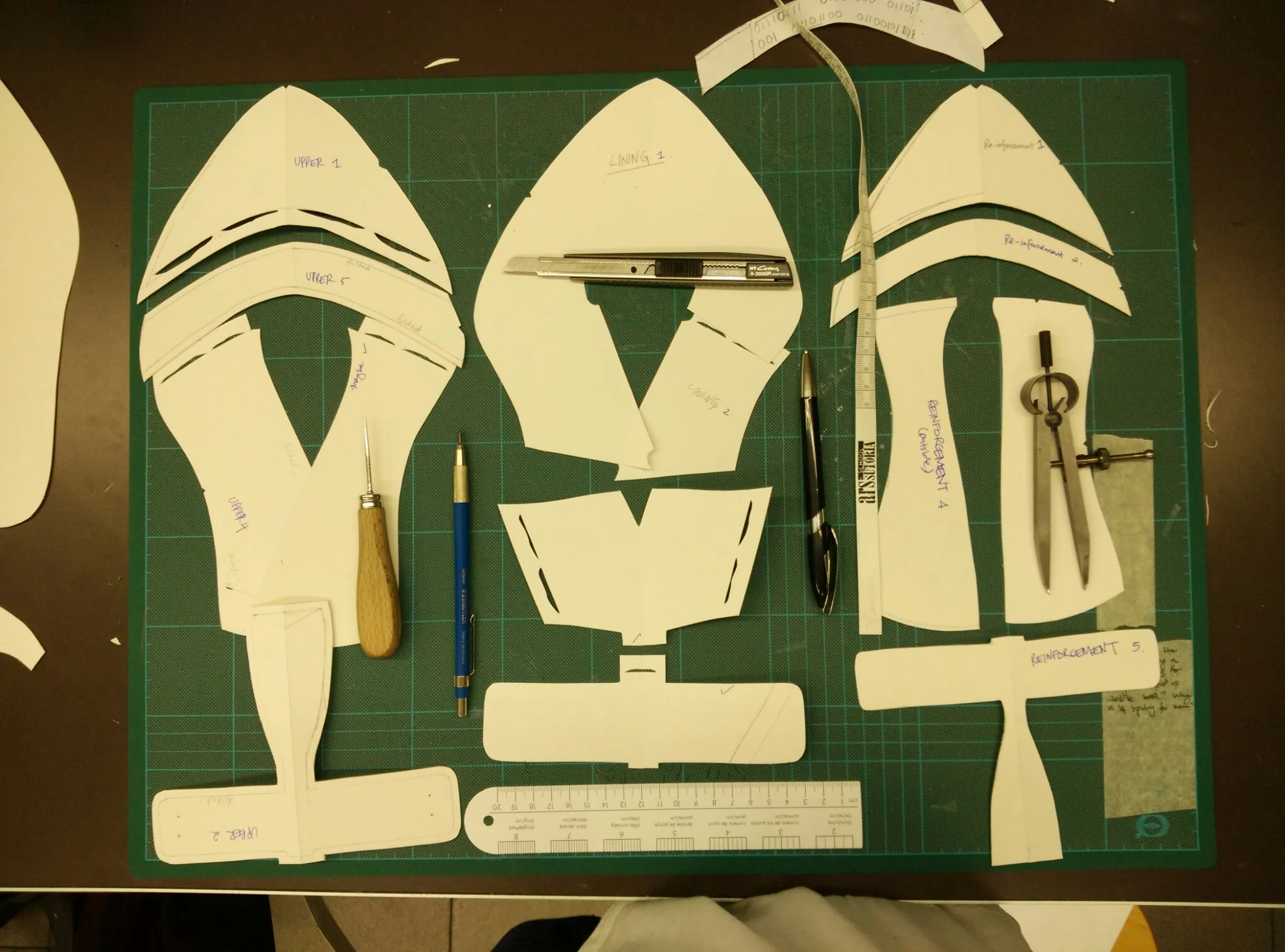

In the summer of 2105, I moved to Milan to learn the process of shoemaking. Shoemaking requires an incredible amount of accuracy since shoes must serve the function of walking and comfort. In the initial months of the course, we would dedicate a week on a type of shoe: oxford, derby, ankle boots, monk straps, T-bars, sandals, knee high boots. The process included measuring and drawing, and then cutting a master. We would use the master to make paper shoes to understand fitting.

Complete master of a monk strap style shoe

Design & make your own shoe

The last few weeks were spent on creating your own design. We picked the style of shoe (in my case, a pump and a sandal), and went through the process of: design, choosing materials, cutting, stitching, lasting, and then fitting.

I chose to represent the idea behind my shoe through binary.

Handlasting requires a lot of strength to pull on the upper and nail it in, so that the upper can take shape.

The complete upper of the shoe, ready to be lasted

Fully lasted